New automatic MADE IN ITALY production lines for standard surgical protection masks

Scroll down for more details

New automatic MADE IN ITALY production lines for standard surgical protection masks

- The lines produce standard surgical masks.

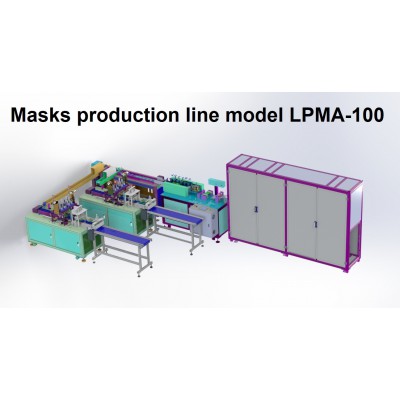

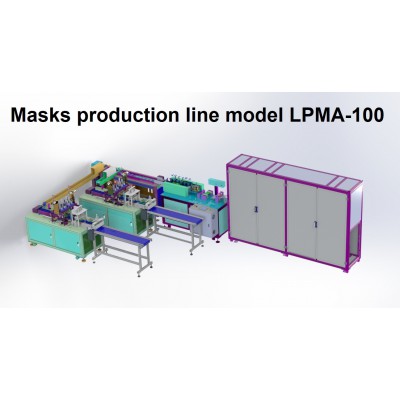

- Models of lines: LPMA-100, LPMA-60, LPMA-50

- Plants capable of managing up to 4 filtering layers in non-woven(roll material).

- Production capacity LPMA-100: 100 masks/minute - equal to 6.000 masks/hour.

- Production capacity LPMA-60: 60 masks/minute - equal to 3.600 masks/hour.

- Production capacity LPMA-50 (a line in container 20' with plug-and-play technology): 50 masks/minute - equal to 3.000 masks/hour.

- Possibility of inserting the clamp/nose.

- Dimensions of line LPMA-100: 8.000x5.000 mm.

- Dimensions of line LPMA-60: 6.000x5.000 mm.

- Dimensions of line LPMA-50: a container 20'

- Electrical power required LPMA-100: 15kW at 380V - 50Hz (3phases + Neutral).

- Electrical power required LPMA-60: 10kW at 380V - 50Hz (3phases + Neutral).

- Electrical power required LPMA-50: 10kW at 380V - 50Hz (3phases + Neutral).

- Welding of the layers by ultrasonic device.

- Newly built automatic line totally MADE IN ITALY.

- Electronic and pneumatic components of primary brands: Omron, Siemens, SMC, Festo, etc.

- Number of entry for material from non-woven roll: 1

- Number of exits for the finished masks LPMA-100: 2

- Number of exits for the finished masks LPMA-60: 1

- Number of exits for the finished masks LPMA-50: 1

- Upon request is possible to supply a bagging machine for each masks exit, with programmable packaging in bags from 1 to 10 masks.

- Upon request is possible to insert on line a mask sterilization unit with infrared irradiators.

- All lines follow the European initiative Industry 4.0, so they are suitable for remote assistance.